Commercial Building Services Insulation: Reducing Energy Loss, Carbon Emissions and Costs

- What Is Commercial Building Services Insulation?

- How Services Insulation Improves Energy Efficiency in Commercial Buildings

- Cost Savings from Insulating Pipes and Ductwork

- Reducing Carbon Emissions Through Services Insulation

- Pipe Insulation in Commercial Buildings

- Duct Insulation and HVAC Performance

- Valves, Flanges and Plant Equipment

- Compliance, Standards and Best Practice

- Inspection, Maintenance and Long-Term Performance

- Summary: Why Services Insulation Matters in Commercial Buildings

- Frequently Asked Questions About Commercial Services Insulation

In commercial buildings, a significant amount of energy loss occurs through mechanical and HVAC services rather than the building structure itself. Pipework, ductwork, valves, vessels, and plant equipment are responsible for distributing heating and cooling energy throughout a site, and without effective insulation, a large proportion of that energy is lost before it reaches its intended destination.

Commercial building services insulation plays a vital role in improving energy efficiency, reducing energy consumption, and lowering operating costs. By insulating services such as pipes and ducts, organisations can reduce heat loss, improve system performance, and support carbon reduction targets without altering the building fabric.

This article focuses specifically on insulation to services within commercial buildings, explaining how correctly designed and installed insulation systems can deliver measurable financial and environmental benefits.

What Is Commercial Building Services Insulation?

Commercial building services insulation refers to the insulation of mechanical and HVAC systems that distribute energy around a building or facility. These systems are essential to daily operation and typically run for long periods, making them a major contributor to overall energy consumption.

Services insulation commonly includes heating and hot water pipework, chilled water and refrigeration lines, steam and condensate systems, HVAC ductwork and air handling systems, and valves, flanges, vessels, and plant equipment.

Unlike insulation applied to the building fabric, services insulation focuses on controlling heat transfer within operational systems, making it one of the most effective ways to improve energy efficiency in commercial properties.

How Services Insulation Improves Energy Efficiency in Commercial Buildings

Uninsulated or poorly insulated services lose energy continuously during operation. Hot pipes radiate heat into surrounding areas, while chilled pipes absorb unwanted heat from the environment. HVAC ductwork can also lose or gain heat as air travels through plant rooms, risers, and ceiling voids.

Insulating services help to reduce heat loss from heating and hot water systems, prevent heat gain on chilled water and cooling systems, maintain consistent air temperatures within ductwork, and reduce system run times and overall energy demand.

By limiting unnecessary energy loss, service insulation improves the efficiency of mechanical systems and reduces reliance on the heating and cooling plant.

Cost Savings from Insulating Pipes and Ductwork

Energy losses from mechanical services translate directly into higher energy bills. Boilers, chillers, and HVAC systems must work harder to compensate for heat loss or heat gain, increasing fuel and electricity consumption.

Insulating pipes and ducts helps reduce operating costs by lowering fuel consumption for heating systems, reducing electrical demand for cooling systems, improving plant efficiency and extending equipment lifespan, reducing maintenance issues caused by temperature fluctuations, and reducing spend on building fabric damage caused by condensation issues.

In many commercial buildings, services insulation offers a relatively short payback period, particularly where systems operate continuously or across large pipe and duct networks.

Reducing Carbon Emissions Through Services Insulation

Improving energy efficiency is a key component of carbon reduction strategies. By reducing energy consumption, service insulation helps lower associated greenhouse gas emissions.

Lower energy use results in reduced gas and electricity consumption, lower Scope 1 and Scope 2 emissions, and improved environmental performance across commercial operations.

For organisations working toward net-zero targets or environmental reporting frameworks, insulating services provides a practical and measurable route to reducing carbon impact.

Pipe Insulation in Commercial Buildings

Pipe insulation is essential for maintaining system temperatures and minimising energy loss within heating, cooling, and process systems.

Common applications include heating and hot water distribution pipework, chilled water and refrigeration lines, steam and condensate systems, and process pipework within commercial and industrial facilities.

Correctly specified pipe insulation helps maintain temperature stability, reduce heat loss, protect personnel from contact burns, and improve the reliability of mechanical services.

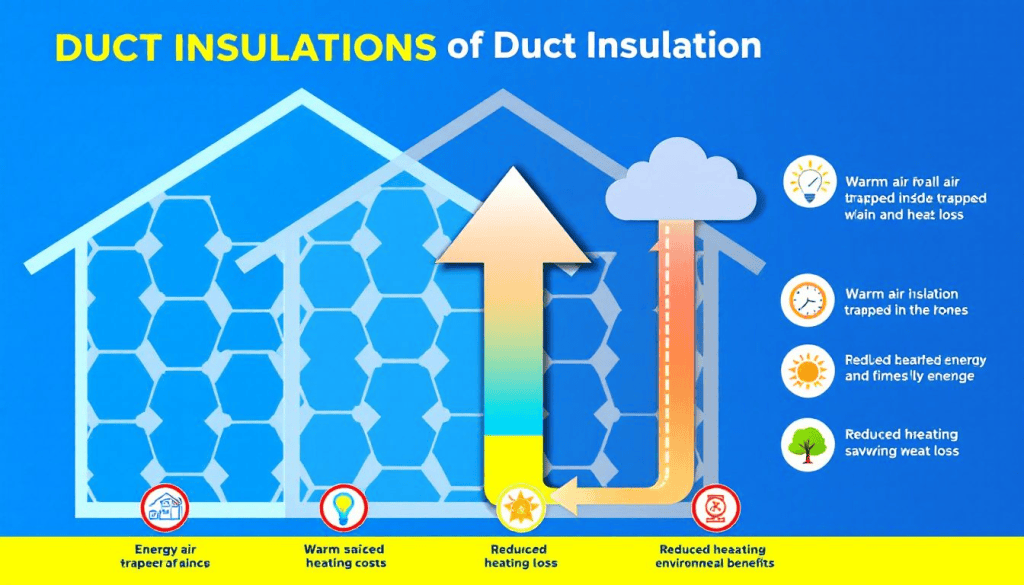

Duct Insulation and HVAC Performance

HVAC ductwork carries conditioned air throughout a commercial building. Without insulation, air temperature can change significantly before reaching occupied spaces, reducing comfort and increasing energy demand.

Duct insulation helps maintain air temperature and thermal efficiency, improve HVAC system performance, reduce condensation risk on chilled air systems, and minimise noise transmission.

Insulating ductwork is particularly important in plant rooms, risers, and unconditioned spaces where temperature differences are greatest.

Valves, Flanges and Plant Equipment

Valves, flanges, and plant equipment are often left uninsulated for access reasons, but these components can represent significant points of heat loss.

Removable insulation solutions, such as insulation boxes or jackets, allow ongoing access for inspection and maintenance while reducing heat loss from exposed components and improving overall system efficiency.

Addressing these areas ensures insulation performance is consistent across the entire system.

Compliance, Standards and Best Practice

Services insulation is typically designed and installed in line with recognised industry standards and guidance, including BS 5422 for thermal insulation of pipework and equipment and CIBSE guidance on energy efficiency and building services.

Adhering to recognised standards helps ensure insulation delivers reliable performance and supports wider energy efficiency objectives.

Inspection, Maintenance and Long-Term Performance

To maintain effectiveness, insulation systems should be inspected periodically. Common issues include mechanical damage, missing or degraded insulation, moisture ingress, and poorly fitted sections.

Regular inspection and maintenance help preserve energy savings and ensure insulation continues to perform as intended throughout its service life.

Summary: Why Services Insulation Matters in Commercial Buildings

Insulating mechanical and HVAC services is one of the most effective ways to reduce energy loss, lower operating costs, and cut carbon emissions in commercial buildings.

By focusing on pipework, ductwork, and plant equipment, services insulation improves system efficiency without altering the building fabric. When correctly designed, installed, and maintained, it delivers long-term financial and environmental benefits.

Frequently Asked Questions About Commercial Services Insulation

Expert Guides

Our goal at Thermal Clad is to not only provide our customers with the finest service possible but also to keep them informed about new products and industry trends.

Please feel free to check out some of our expert insulation guides below:

Commercial Building Services Insulation: Reducing Energy Loss, Carbon Emissions and Costs

In commercial buildings, a significant amount of energy loss occurs through mechanical and HVAC services rather than the building…

How to Prevent Condensation and Corrosion Under Insulation (CUI)

Corrosion Under Insulation (CUI) is a well-recognised issue in industrial environments and continues to be a cause of unplanned…

Sustainable Insulation: Reducing Carbon in Building Services

Sustainable insulation materials are an important part of reducing carbon emissions within modern building services. Mechanical and electrical systems…

What Is Trace Heating? A Complete Guide to Trace Heating Systems, Heating Cables, and Service Pipework Protection

Trace heating plays a crucial role in keeping industrial and commercial services operational in cold or fluctuating conditions. If…

BS 5422 Explained – Insulation Thickness Standards for Energy Efficiency & Compliance

At Thermal-Clad, we’re often asked how to make sure pipework insulation meets the latest standards while delivering the best…

Thermal Insulation Types for the Industrial Sector

Thermal insulation is essential in industrial construction, reducing energy consumption, improving workplace comfort, and protecting buildings and equipment from…

Cladding In Construction: What It Is And Its Purpose?

Cladding in construction refers to the process of covering insulated pipework, ducting, and vessels with a new layer of…

Pipe Insulation Benefits And Why It’s Important

Pipe insulation involves wrapping pipes with material to reduce heat loss and regulate temperature. This process helps maintain water…

Ductwork Insulation: Benefits & Guide

Duct insulation is essential for ensuring your HVAC systems operate efficiently by minimising temperature fluctuations during air transfer. It…

Heat Trace Cable: What Is It And How Does It Work?

Heat trace cables prevent pipes from freezing by generating heat. Curious about how heat trace cables work? This article…